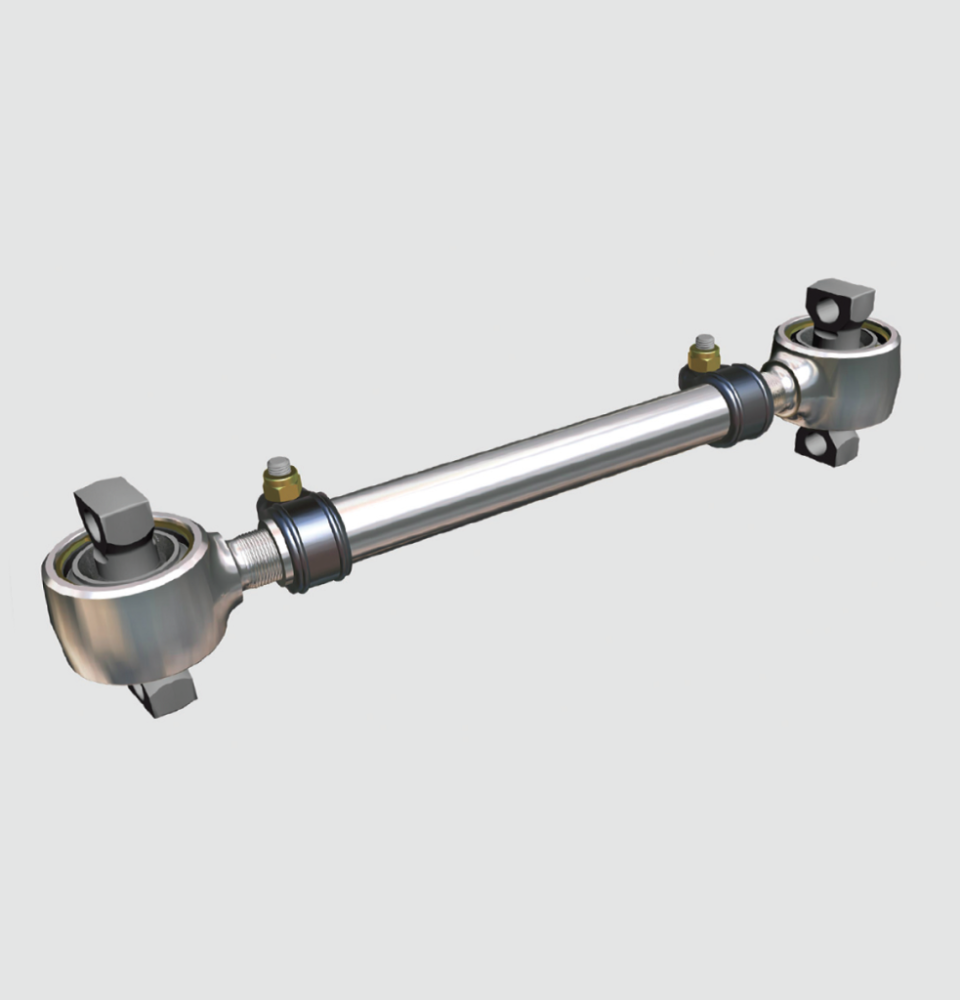

High-quality Panhard bars from Pailton Engineering

Simple and effective, the Panhard bar – also known as the Panhard rod – has remained relatively unchanged in 100 years. Pailton Engineering combines this classic design with modern manufacturing techniques to ensure durability and performance over thousands of miles.

Why Choose Pailton?

- We can accommodate any trunnion installation length and angle

- Advanced CAD technology and state-of-the-art optical scanning equipment for reliability

- Designs undergo rigorous fatigue testing to ensure high quality and performance

- We supply world-class steering and suspension components to industries where reliability is critical, including defence, commercial and public transport sectors.

Panhard bar design

A key consideration when manufacturing Panhard bars is ensuring that they are resistant to bending and fatigue. These forces are strong in heavy-duty uses like trucks and buses. Increased load and side forces can stress suspension parts, so we design our bars to handle these forces. They maintain alignment and last longer, even in extreme under-chassis environments.

For optimal performance, the bar's placement and design are crucial. It should be as long as possible and positioned near-horizontal. This reduces the potential for the axle moving in an arc during vertical suspension travel, which would introduce lateral movement.

Adjustable Panhard bars help maintain rear axle alignment when the vehicle's ride height changes. This might happen after a suspension upgrade. Adjusting the length of the bar ensures that the axle remains aligned and that tyres wear evenly.

Our bars are also used as damper struts in the axis of the chassis. When the vehicle is braking, the bar provides flexible support.

The role of a Panhard bar in vehicle stability

In vehicles with a solid axle and coil spring suspension, the axle can shift side to side. This happens when bushings deflect during turns or on uneven roads. This lateral movement, if unchecked, can make the vehicle feel unstable.

The Panhard bar helps prevent lateral movement, keeping the axle aligned with the chassis and ensuring stable, predictable handling. The bar operates by providing a rigid lateral link between the axle and the vehicle’s frame.

Without this suspension link, drivers would experience imprecise steering and reduced handling, especially during turns. They also help to eliminate ‘bump steer’.

To discuss your vehicle’s specific design needs, or to explore our range of Panhard bars, contact Pailton Engineering today for a free consultation.